KTM 250 Cylinder Heads

What's the difference?

By Alan Buehner

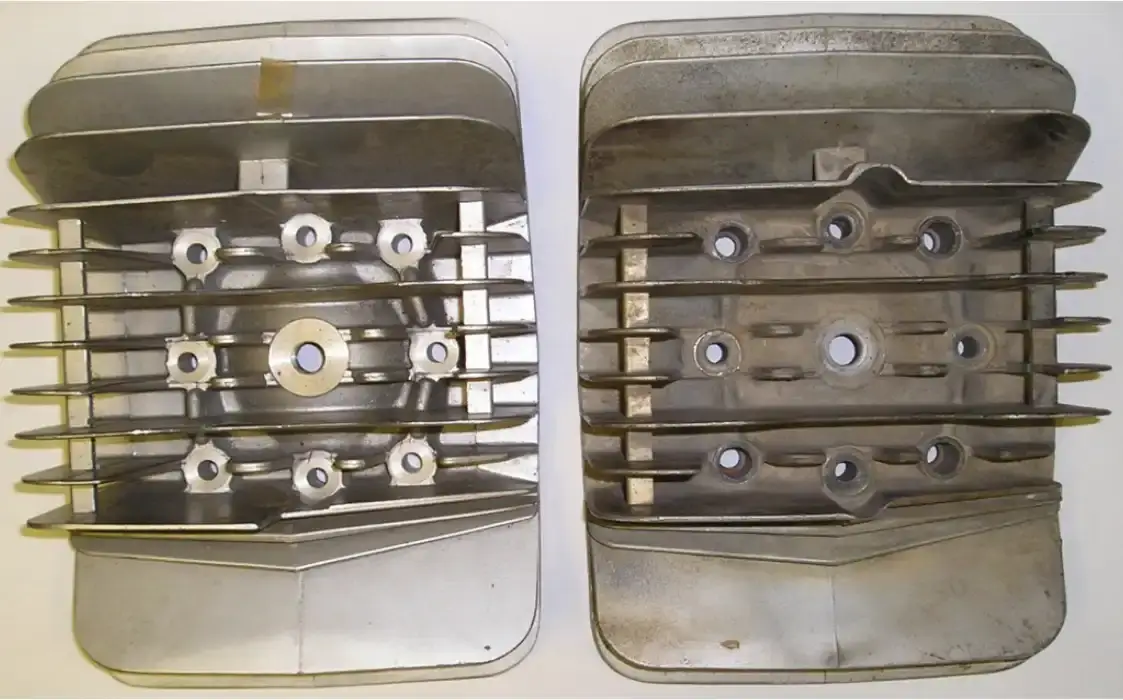

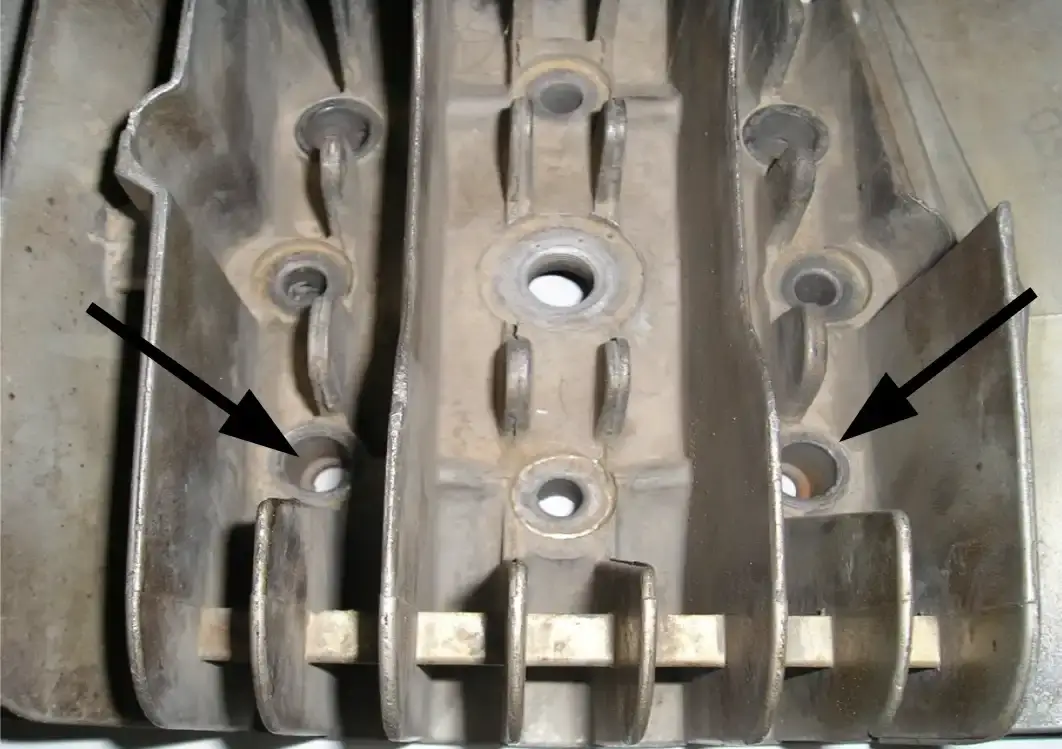

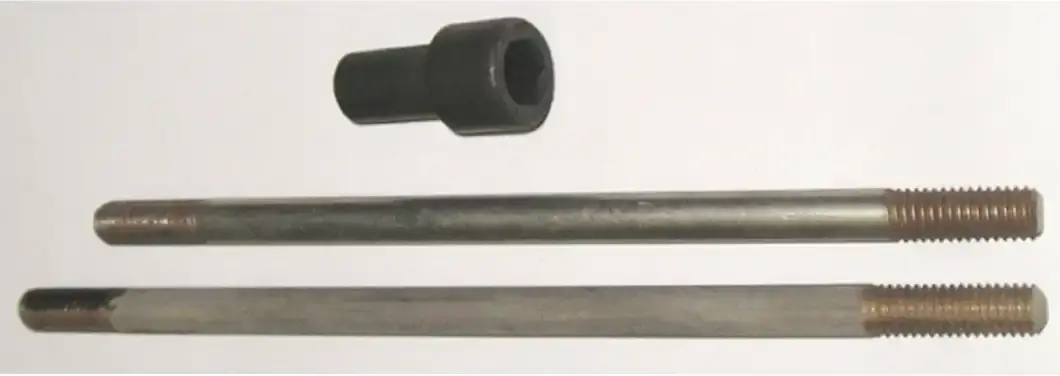

If you don't know any better, you will just assume that all of the KTM 250 cylinder heads are the same and are interchangeable (see photo A). They are interchangeable but not the same. When the 250 engines were designed and produced in 1973, they came with 6-5/8” long cylinder studs (see photo D). They cylinder head was fastened to the stud with a 8mm washer and a regular 8mm nut.

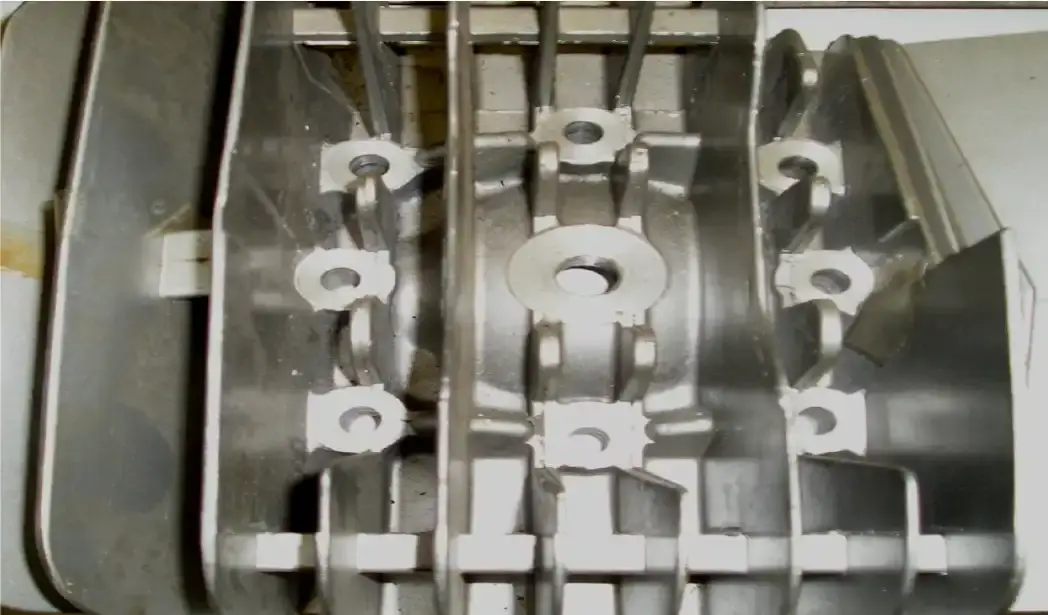

I think that it was some time in 1975 that the engineers decided to modify the cylinder heads and use a special Allen Head cylinder nut (see photo D) to secure the cylinder to the studs. To compensate for this change, the studs were shortened to 6” long (see photo D).

Both styles of heads have the same KTM part number 54-30-006-000 cast into the bottom of the cylinder. So, the only way to identify them is by the diameter of the cylinder stud holes.

If you are missing a cylinder and/ or head, this is good information to know. By measuring the studs on the bottom case (if they are still there) you will know what style of cylinder head that you will need.

If you have the cylinder head, but are missing the cylinder studs, you will then know what size stud you will need and if you also need the special Allen Head nut.

The 6-5/8” long stud is KTM part number 54-30-043-000.

The 6” long stud is KTM part number 51-30-043-000.

Both studs are 8mm in diameter.

The special Allen Head nut is number 55-30-044-000. It is also used on the KTM 400 cylinder heads. It measures 1-1/4” long. The thin part of this nut is 12mm in diameter and is 3/4” long.

Tightening Torques for nuts and bolts

Cylinder studs – 8MM - 12 foot pounds

Cylinder stud nuts - 18-20 foot pounds

8x40 Allen head bolts - 18-20 foot pounds

Tightening sequence – Tighten the Allen Head bolts first so that the cylinder head is centered on the cylinder. Tighten crosswise – left, then right, then bottom, then the top bolt. Finish by tightening the corner stud nuts in a cross pattern.