Pistons, Cylinders & Reboring

by John Cobb

Reprint of "Let's Do It Right" Jan 1973 issue no.2 of "Keeping Track" newsletter (PDF available here.)

Generally, this article could be a base for most piston work, but it is directed toward our Penton owners and their machines.

First, when should you rebore or replace a piston?

- On a 100cc Penton, when you get .005" clearance.

- On a 125cc Penton, when you get .005-1/2" to .006" clearance.

- On a 175cc Penton, when you get .006" to .007" clearance.

- On a 250cc Penton, when you get .006" to .007" clearance.

- On a 400cc Penton, when you get .006" to .007" clearance.

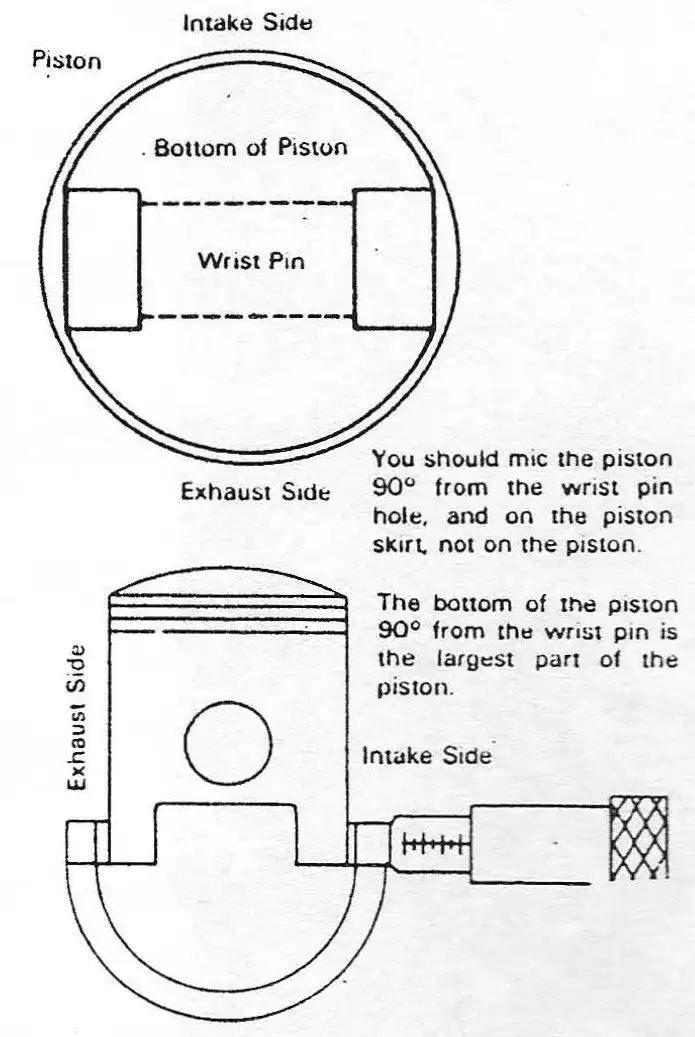

Now here is how you measure the piston and what you will need:

1. Most people do not have micrometers, which is the most accurate way for measuring the piston clearance, but if you do have access to one, use it.

In otherwords, the piston is built in the form of a taper and is shaped like an egg. The largest part being the front and back at the bottom of the piston.

2. Now you know the piston size. We have to find out the cylinder size.

The cylinder is not tapered or egg shaped and should not get this way. It shouldn't have any grooves in it where something has broken and was tearing up the cylinder wall. A good cylinder should have a good cross hatch pattern.

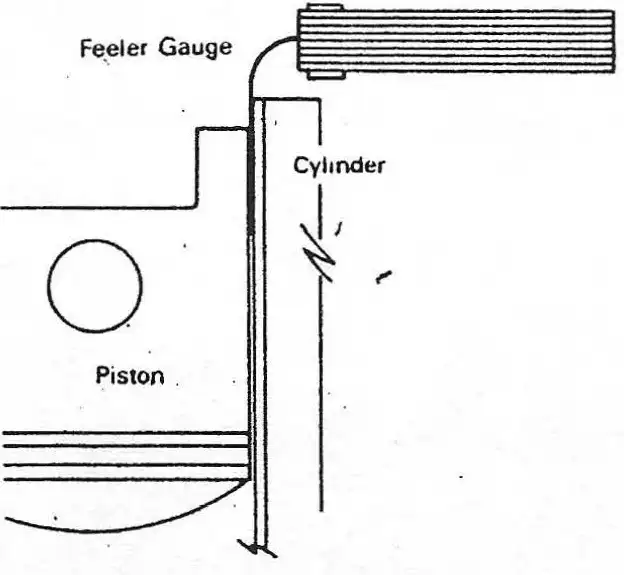

To check the size of the cylinder, you should have an inside micrometer. But if not, we can still check piston to cylinder clearance. What you will need is a feeler gauge.

A. The best way is to take the rings off the piston, and insert the piston in the cylinder the way it would normally run. After doing this, try putting the blades of the feeler gauge in between the cylinder wall and piston. Do this until you get a drag on the blade. See how many thousands it has, and you will know the clearance.

The clearance should be checked at the top of the cylinder and the bottom. This is to see if there is any taper.

B. The most accurate way is with an inside micrometer and it should always be used whenever possible. The way it is done is by inserting the inside micrometer at the bottom and checking the size, then do the same at the top. See if there is any difference between the top and bottom. If there is, you will know how much taper the cylinder has.

C. Now, you will need to know the clearance between the piston and cylinder using an inside micrometer. The best way is to take the largest reading off the cylinder, then the piston reading, and subtract it. You will then have the clearance.

EXAMPLE: Cylinder reads 2.128, Piston reads 2.121. The difference is .007" clearance.

The clearance is too much.

Note: If there is very little taper to the cylinder like . 00 l" and the clearance between cylinder is . 003" this small amount of taper will not hurt.

D. All measurements taken on the inside micrometer should be retaken on the outside micrometer to be accurate and less possible chance of mistake.

3. Now let say you found .005" clearance between piston and cylinder (which is borderline on a 125cc).

A. Look at the cylinder. If the cross hatch is still in it and there are no bad scratches, the cylinder is probably all right and not worn. So take the piston and mic it, and then mic a new one of the same size. If the new one is . 002" larger than the used one, this would give you .003" piston to cylinder clearance, which is good. So you would just break the glaze in the cylinder with a surface hone and install a new piston and rings.

B. A piston will usually wear more than the cylinder, because it is made of aluminum. By checking pistons for wear and not having to rebore, you will get much longer cylinder life.

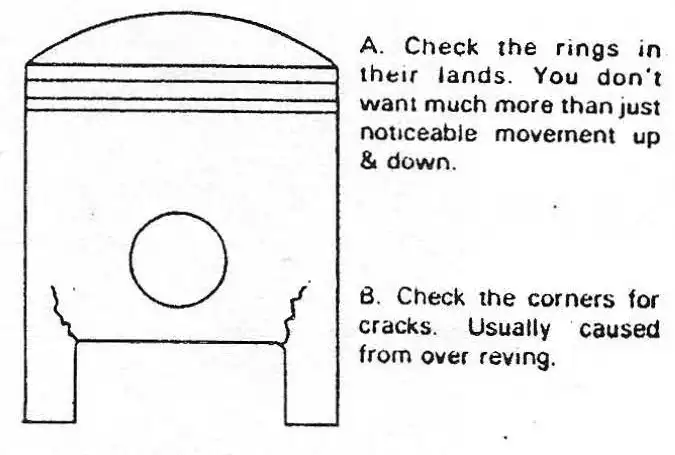

4. Lets say the cylinder to piston clearance is within limits and a rebore is not needed. That does not mean the piston is in good shape.

On our 175cc Jackpiner the clearance should be checked often. Keep a close look for cracks on the piston. Remember if a piston skirt breaks off, it may cost you a new cylinder, connecting rod, piston and possibly a set of cases. The reason the 175 is more critical, is the way the piston is made.

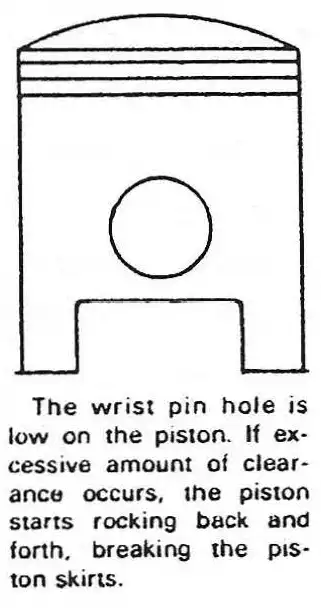

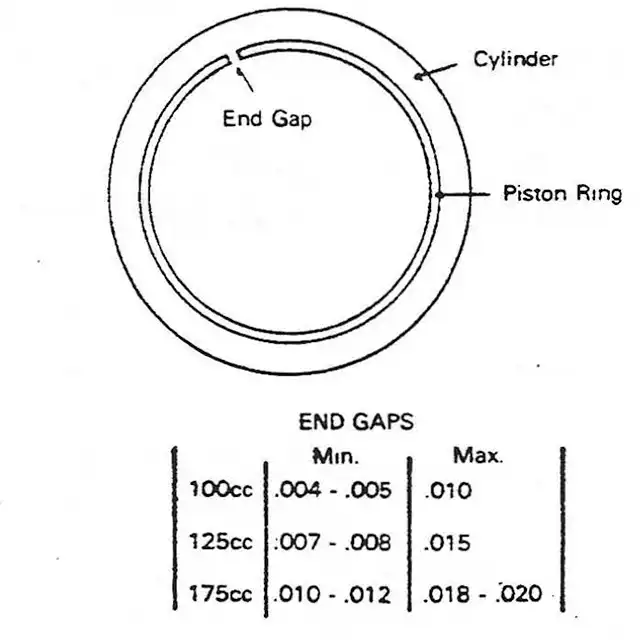

5. Piston rings and piston clearances.

A. Piston rings should have noticeable up and down movement in their ring lands, which is about . 002" movement. If excessive amount of up and down movement is found, the piston should be replaced. Whenever installing new rings, be sure and check this, plus end gap. this wear in ring lands comes from dirt, water and high R.P.M.'s (over revving).

B. End gap. This is checked by inserting just the ring in the cylinder. You should put the ring in square in the cylinder about 1/2" to 3/4" down from the top of the cylinder. Then take a feeler gauge and check the gap. Check both rings. Usually you do this if you are only replacing rings and using an old piston. Be sure and clean all carbon from ring lands before installing new rings on the piston. Ring end gaps for 250 & 400 should not exceed .027" (0.7mm).

C. Piston to cylinder clearances for reboring cylinders:

100cc - .0015" to .002"

125cc - .0025" to .003"

175cc - .003" to .0035"

250cc - .0025" to .003"

400cc - .003" to .0035"

These are the clearances you should use when reboring cylinders.

Editor's note: these measurements are for the Mahle pistons. When using a Wiseco piston, bore the cylinder slightly larger to allow for piston expansion when it heats up. This will prevent it from seizing up in the cylinder

Remember, whenever you rebore a cylinder, be sure and round or radius the top and bottom edges of all ports. This is so the rings will not catch in the port and break them causing much damage. Remember, every little thing counts in reboring. A cylinder and piston set-up properly will give good power and reliability for many hours.

99% of piston and ring wear is dirty air, water and excessive high R.P.M.'s. Your cylinder and piston are only as good as the air filter system. Keep your air box and filter very clean and well sealed from dirt and water.