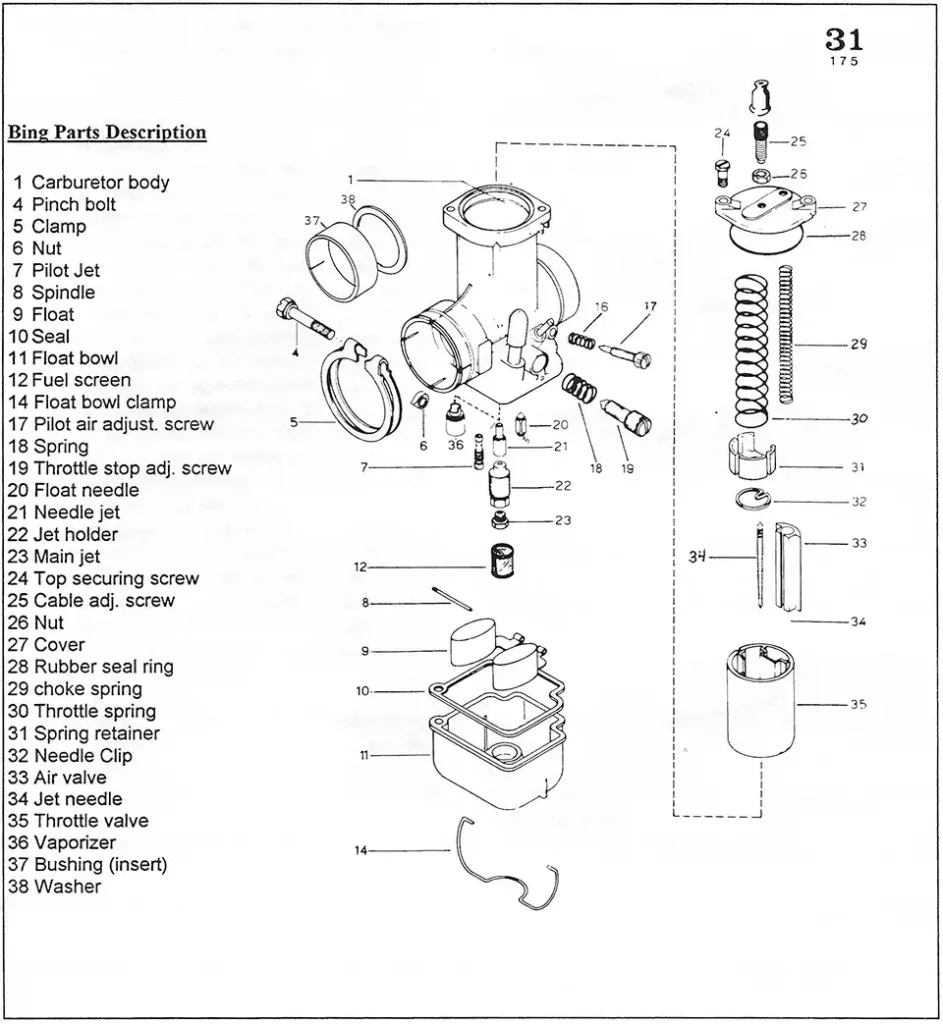

Bing Carbs 101

by Bobby Lucas

Originally printed in 2000 issue #6 of Still….Keeping Track

Penton motorcycles generally have a Bing carburetor mounted from the factory. When properly adjusted and maintained it will give the rider outstanding performance and reliability under all types of conditions!

Under the current vintage competition rules, the Lectron carb and other "flat slide" carburetors are not allowed. Early Jackpiners came with the Amal carb. However, in this article we will be talking only about the Bing carburetors.

The Bings mounted on 125s are 30 or 32mm and have the codes of 2/30/101. The 175s are 30 or 32mm and have the code of 2/30/102. The 250s are 36mm and are coded 2/36/102. The 400s are 38mm and are coded 2/38/102. The later model 125s and 175s had 34 or 36mm carbs and the 250s had 38mm carbs. The codes are stamped on the carb bodies.

The Bings mounted on the KTM powered Penton motorcycles were of two types. Type "one" were on all motorcycles up to 1976. Type "two" were mounted on Pentons in 1977 on through the life of this engine type. You can use a late model type "two" on an early model engine, but you must replace the intake manifold and rotate your air boot to fit. Your pipe will be very easy to remove when you change to the type "two".

Type "one" carbs were mounted in a couple of ways. On some the carb body mounted (clamped) directly to the manifold. The later types had a special insulating insert between the manifold and the carb to prevent wear due to engine vibration. Type "two" carbs were rubber mounted.

Carburetors are a fuel/air metering device which measure the amount of air entering a reciprocating engine and sprays into this air the correct amount of fuel for the desired condition of engine operation. The metering of the fuel to be mixed with air is the function of all carbs. Pressure is the key along with properly sized and adjusted components. Pressure is created by a good Piston. A worn piston may not provide the carburetor proper pressure to mix enough air and fuel causing a cold running (rich) engine.

Inspect your Bing in the following ways and you can use it a very long time. Check the carburetor mount for wear and any cracks at the clamp area. If your Bing is loose, trying to put six extra turns on the clamp screw & bolt, or using a larger bolt and nut will only cause you to crack your carb body. The manifold needs to be rebuilt ( or replaced) to the original dimension or the wear of the two parts compensated by the installation of an insert. If your carb is loose and it has an insert (#37), it (the insert) needs to be replaced.

Check your slide pin located on the inside wall of the carb body. I usually RTV it to prevent any movement of the pin and to prevent any air leakage through the outside part of the pin area. Remember, if air can get in , dirt and water can too.

Check your cable adjusters (#25) on the cap of the carb. Replace any worn parts. Check your tap screws on the cable adjusters for stripped threads or worn flats (from the cable). Replace your rubber o-ring washer (#28) on the cap. Never ride without it.

Check your slide spring (#30) for wear. A worn spring is one that is weak. Don't stretch this spring ever! Check your choke cable adjusters (#25) and spring (#29). Replace any worn parts.

Caution: never over tighten any of the adjusters on the cap

Check your spring retainer. I like the plastic retainer (#31) (part #51- 31-131-000 / or Bing #26-511 for the 175s and part# 55-31-131-000 I or Bing #26-512 for the 250s). This plastic retainer is very important. Never leave it out or your throttle cable will slip off the slide and you will not be happy when out riding. Early Bings had a metal flat washer and if you can, replace it with the plastic type.

Next, check your jet needle (#34) and the needle clip (#32) for wear. I highly recommend replacing both. I am a victim of a cut needle which thankfully fell into the needle jet and not into the engine.

The throttle slide (#35) will be a great indicator of the type of performance you will be able to create. If your slide front is worn and pitted badly, you will need to replace it. On type "one" carbs, Bing (Agency) cannot replace the slide. On type "two" carbs, Bing (Agency) has new ones in stock.

A dirty filter, an engine loose in its mounts, and an engine that is vibrating will wear the slide, needle, and needle jet to a point that a rich mixture is all you will get. Remember, keep it clean and tight.

Needle jets (#21) are made of brass and the needle is of steel. The up and down movement and the pressure from your cylinder will cause your needle to wear out your needle jet. You can tell the wear by looking at the small end (top) of the needle jet. An egg shape center means you need to replace the needle jet. Replace it ·with the same size or buy a smaller one and drill it to the original size.

Vaporizers (#36) (or mixing devices) need to be checked for wear or chips. I've seen some that are gone and the engine really will run rich.

Tickler assemblies should be checked to see if the clip holding the tickler in the body is worn or about to slip off Replacements are easily had. I've reached down and tickled the carb and let the tickler go only to see it shoot out of the carb. Not a good thing on the starting line!

Float needles (#20) should be replaced if worn. A ring around the top of the needle point will mean you need to replace it. Use only the same type of needle. If a wire clip is used to attach it to the float, always use it again.

Screens (#12) are provided in Bing carbs for dirt riding use. It is to keep fuel from surging into the engme while riding on rough terrain.

Bowl gaskets (#10) should always be replaced at overhaul time or if they are torn.

By the information provided in the Penton Operation and Maintenance manual and by some of the pointers I have given you in this article, you should have a smooth running, easy starting, reliable motorcycle. See ya at the starting line.