Special Engine Tools II

by Alan Buehner

Photos by Kip Kern

Originally printed in the 2011 issue #50 of Still….Keeping Track

In the last newsletter, I showed and explained how you can make some of the “hard to find” special tools that are needed to perform repairs and maintenance on the Sachs and KTM engines. Since then, I have talked to Kip Kern and these are some of the tools that he has bought or made to work on Sachs and KTM engines.

Sachs M-20 bearing outer race puller. This is a large blind bearing puller that can be purchased from a bearing supply house (such as Applied Industrial). The tool is inserted behind the lip of the race then bolt is screwed in to expand the fingers of the tool. Engine case is heated, placed in a press upside down and then tool is pushed out of the bottom of the case..

KTM clutch basket holder. If you know how to weld, then this is an easy tool to make. Kip uses 2 old clutch plates, slides them over an inner clutch hub (to keep them lined up) and welds them together, then welds a handle onto them. The handle should be approx. 18mm wide so that it will fit between the fingers of the clutch basket

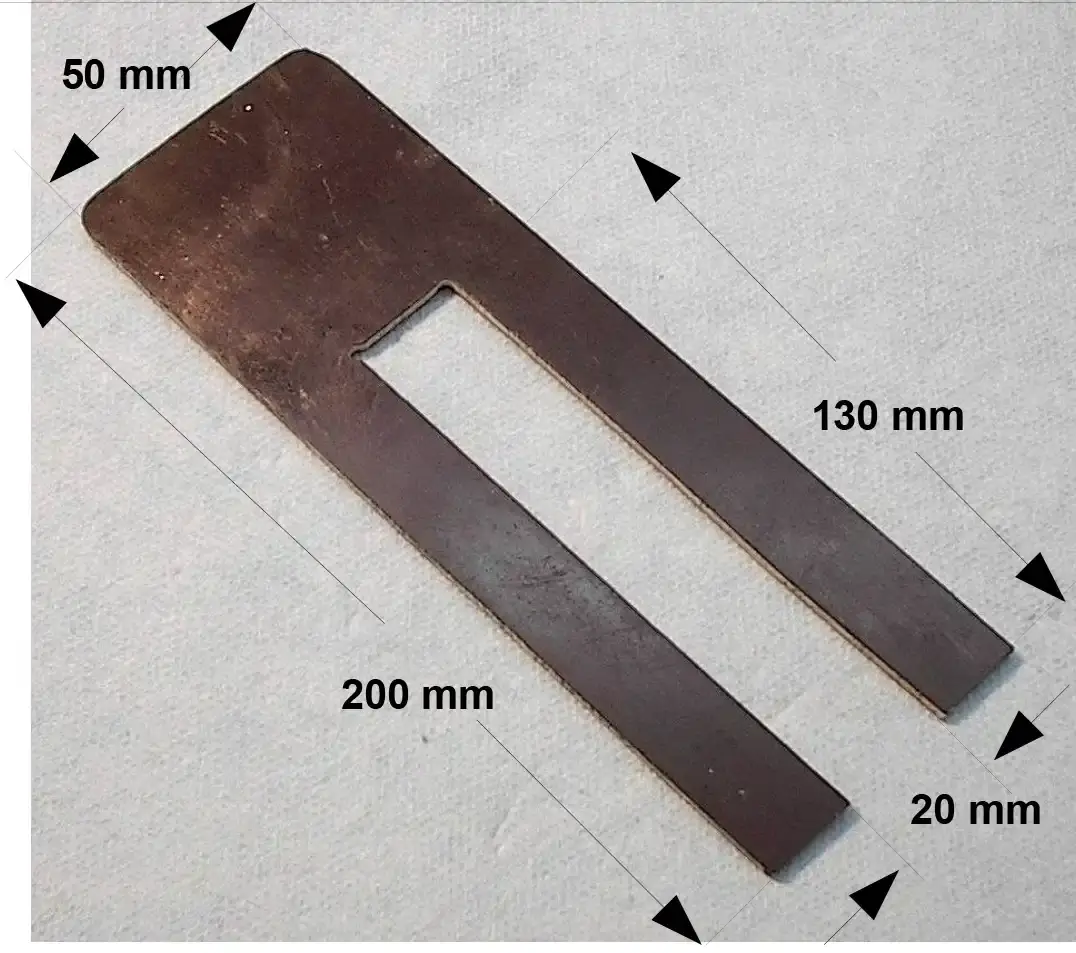

Piston rest to install all cylinders. This can be made out of plywood or sheet steel and is placed under the piston to hold the piston steady. This frees up your hands to allow you to slide the cylinder down over the piston while you squeeze the piston rings. (Sachs M427 manual)

KTM/Sachs crank bearing inner race puller that can be used to pull the inner races of the 3 piece crank bearings off of the end of the Sachs and KTM cranks. This is an air conditioning fan blade puller that can be purchased at your local heating and air conditioning supplier. It is made by MA-Line – part no. MA-FB2. Kip machined 1/16” off the bottom of his puller to allow some extra play, to center the screws into the groove of the inner race.

HOME MADE KTM TOOLS

KTM Crank Removal & Case Splitter Tool

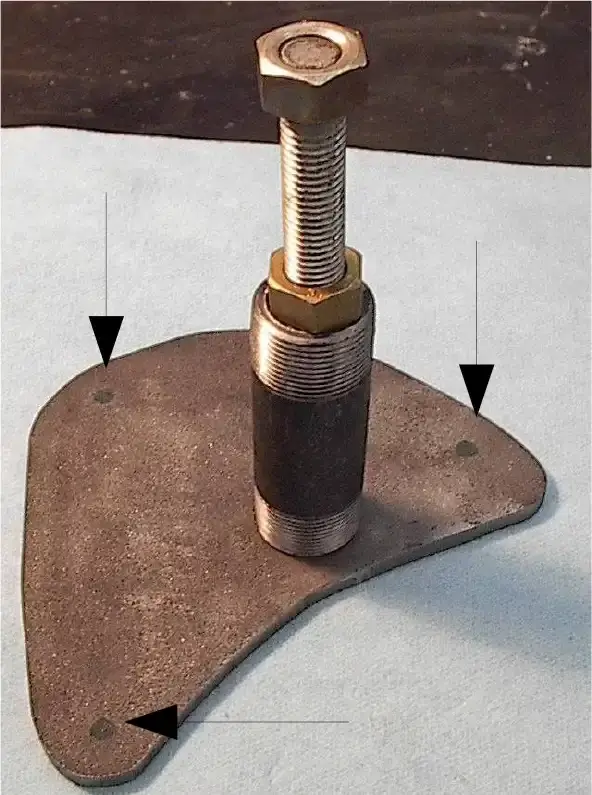

Getting ready to drill, weld and plate a KTM crank pusher.

A plate 1/4" thick was plasma cut to fit the engine case and curved to fit around the clutch basket. The bolt is 6" long and a 1" OD nut is welded to the top of the pipe nipple. The pipe nipple is 3/4 ID and cut 1 3/4" long (service 80 black pipe available from plumbing supply). The hole in the plate is 7/8" diameter. Weld the nipple to the plate, weld the nut to the nipple and thread the bolt in it.

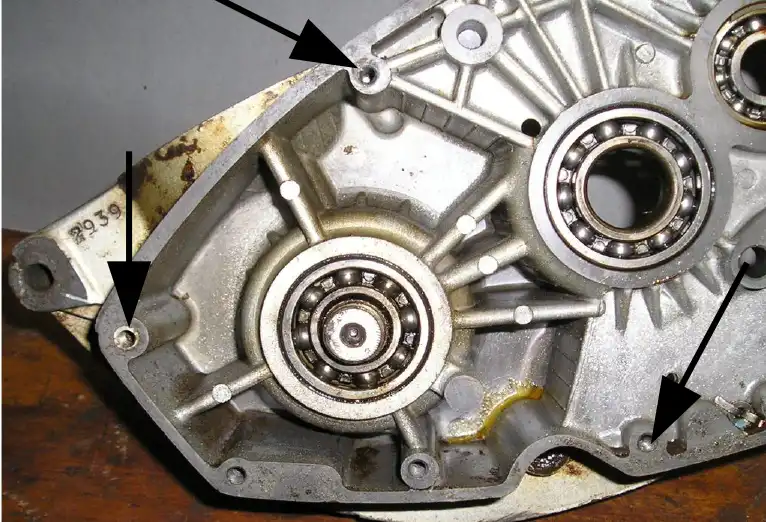

To split the cases, bolt the tool to the cases via 3 each 6mm screws. Thread the bolt down to the left end of the crank, make sure all the Allen screws are removed from the right cases and tighten the bolt easily until the cases split. open the cases and then finish turning the bolt until it pushes the crank out.

The tool is designed to fit over the end of the crank and bolt to the holes shown by the arrows. Plate is curved to fit around the clutch basket without the clutch being removed.

KTM Clutch Nut Tool

A flat blade screw driver is what Kip uses to hold the end of the screws and a hollow tube 10mm socket to turn the nuts.

HOME MADE SACHS TOOLS

6mm Thumb Screws

These were designed by Ted/ Dane Leimbach for use on Sachs holding plates to make it fast and easy to secure the plates to the engine cases.

8mm flat washers are brazed to the heads of 6mm screws.

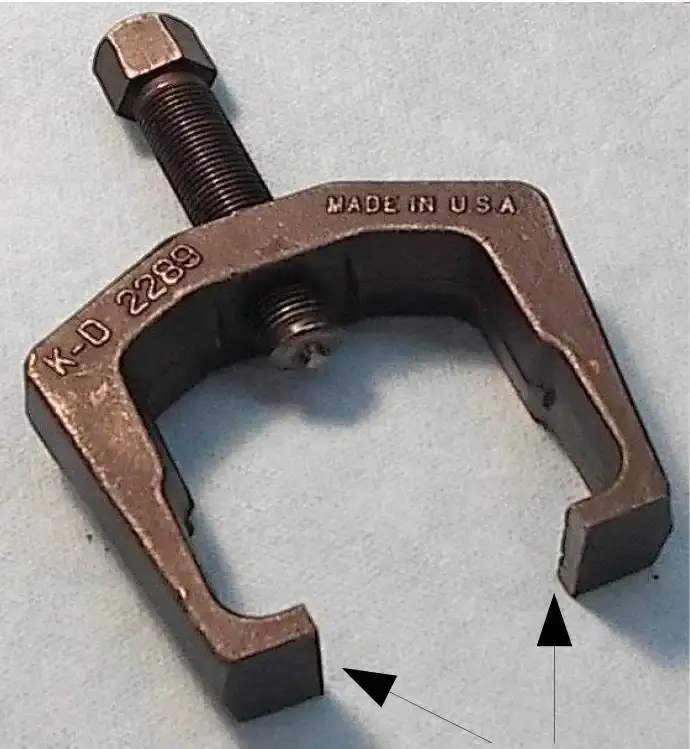

Sachs Counter Shaft Sprocket Puller

This is a modified pitman arm tool (K-D #2289 which is available from automotive stores). The bottom fingers were shortened (shown by arrows) to allow it to fit under the sprocket.

CAUTION: use a 13mm socket over the end of the Sachs mainshaft for use as a protective cap before using any puller. Failure to do so will cause the end of the mainshaft to break.