Keeping your Ignition going

by Alan Buehner

Originally printed in the 2005 issue #26 of Still….Keeping Track

At the Penton Day at the AMA meeting on Feb. 5rh, Dane Leimbach talked about the Motoplat ignitions and some of the problems that can be expected from them. He gave some pointers on them and I thought it would be a good idea to share them with all of our POG members who could not make it to the meeting. This information pertains not only to the Motoplat ignitions, but also the new PVL and MZ-B ignitions.

KEEP THEM DRY

You know that old saying, "an ounce of prevention is worth a pound of trouble"? Well, water and moisture do not get along with ignition systems even if you have a sealed ignition cover. A hot motor and cold water will cause condensation to build up in the water tight compartment unless it is vented. Condensation causes corrosion to aluminum and magnesium and steel to rust. The best way to prevent corrosion after a day of muddy riding or after having just washed your bike is to remove the ignition cover and leave it off until the next time you go riding. This will allow any moisture to dry out.

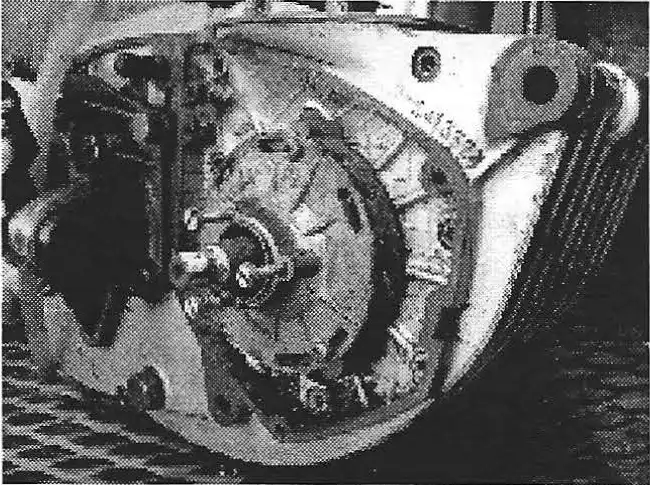

flywheel removed showing mounting

plates and screws.

KEEP THEM GROUNDED

From time to time I get calls from people trying to get their newly acquired Penton to light up. I have shared information that I have learned from other people's stories. Such as, after painting the frame, remove the paint from the engine mounting tabs so the the motor will have good metal to metal contact with the frame. Make sure that the coil mount also has good metal to metal contact. Dane also shared this logical peice of information. All of the mounting points of the Motoplat lgnitons carry a ground and should be rust and corrosion free.

Since the Motoplat Ignition is mounted on a plate which is also screwed to the seal retaining plate ( on the KTM motors) removing and cleaning the mounting screws of the Motoplat will re-establish a good ground between the motor and the stator unit. This is especially important for all KTM motors. The magnesium motors corrode very easily. Over time the mounting screws will corrode and since the seal retaining plates have a gasket between it and the motor, it is the screws that are doing the grounding. This can be a big problem especially if the motor has been sitting for 20 years. In most cases, just removing the screws and retightening them is enough to reestablish the ground.

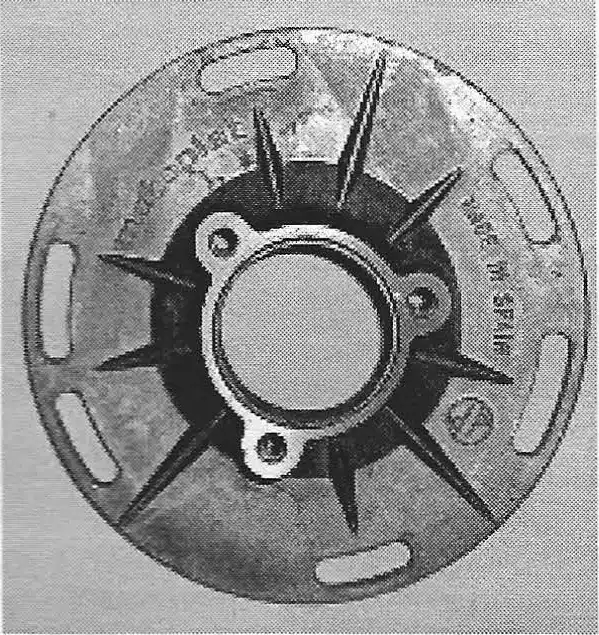

for stator unit used in the Penton

Sachs and KTM motors. It is attached

to the motor with 3 Phillips head

screws. The Stator is then attached

to the mounting plate with 3 pan

head screws.

DON'T KILL YOUR IGNITION

Never kick over a motor without the spark plug connected. Every time an electronic igitiop is spun, it builds up a charge in the internal capacitor that gets discharged when the spark plug fires. If the capacitor is not able to discharge it could overload to the point when it does finally discharge, it will burn out.

Examples of this given by "Speedy" Clasen (Canada) were: Removing the spark plug from the head and not having it plugged into the coil lead ., and resting against the cylinder while kicking the bike over, or drowning your bike in a river crossing, turning the bike upside down after removing the spark plug and turning the rear wheel to pump the water out of the cylinder. "Speedy" recommends keeping a piece of inner tube (rubber band) in your tool kit. If you should run into a situation where you need to pump water out of your motor, put the rubber band around the cylinder to hold the removed spark plug (connected to the coil) to the cylinder so that the capacitor can be discharged while the motor is being turned over. He has personally witnessed riders at river crossings unknowingly bum out their ignitions without realizing what they had done wrong.

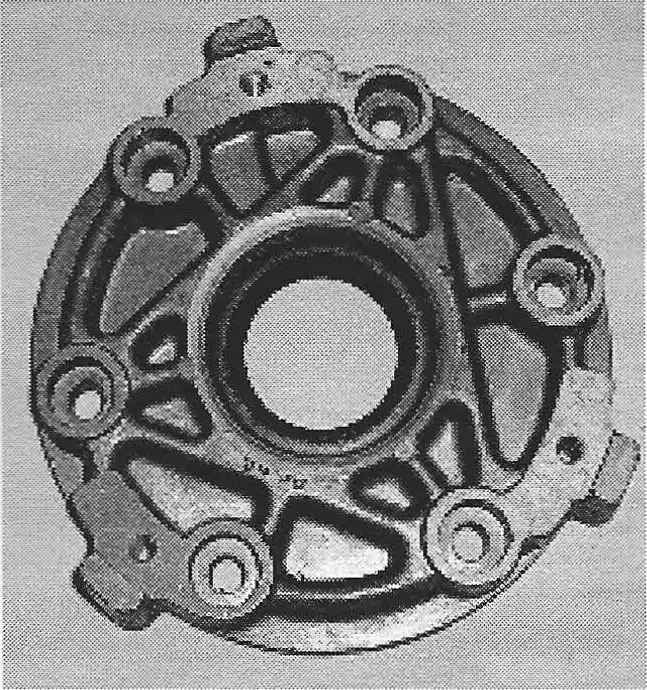

the KTM motors only. It is held in

place by six Allen Head screws. The

Motoplat mounting plate attaches to

this plate with three Phillips head

screws.