Building a 175cc Sachs Motor

by John Durrill

Originally printed in the 2003 issue #18 of Still….Keeping Track

Two men (my son Peter and I); one motorcycle; lots of help.

It started with one 1973 Penton Six-Days and a desire for a motorcycle that would suit an old fat, out-of-shape enduro rider. Actually it just started as a winter project. A desire to have a Penton like "back when", a bike to run the ISDTR, and to ride in the woods at least once a month. We began gathering the bits and pieces to build a new 1973 125 Penton.

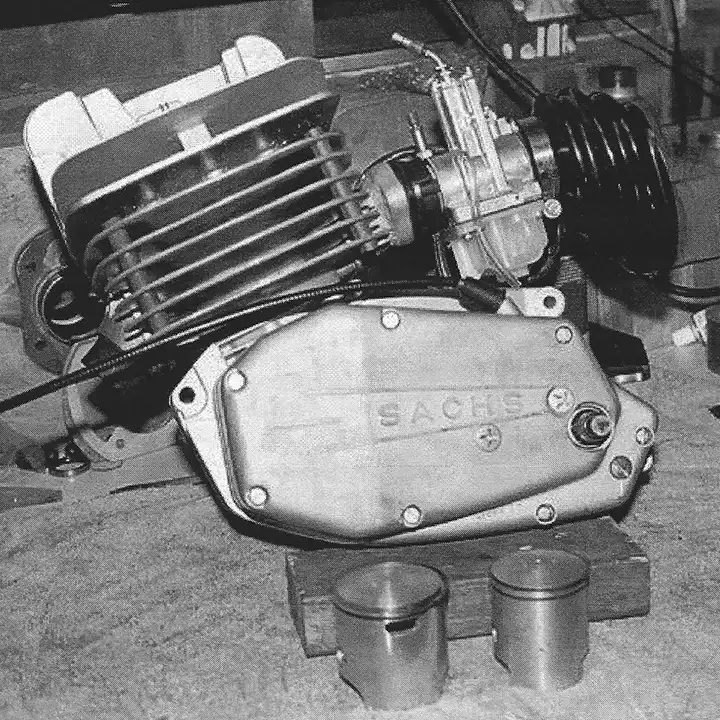

The frame was sandblasted and painted with PJ's KTM silver. An "A" 5-speed motor was built with a set of what we thought were NOS "A" cases. The area where the cylinder resides and transfer ports meet are much larger than a standard A or B engine. We still have not identified what the cases came from.

A trip to the Poteau Mountain Wilderness was enough to see that attacking inclines on a 125cc isn't quite as much fun as it used to be. We knew that we would need a replacement or some displacement for climbing more than sand banks.

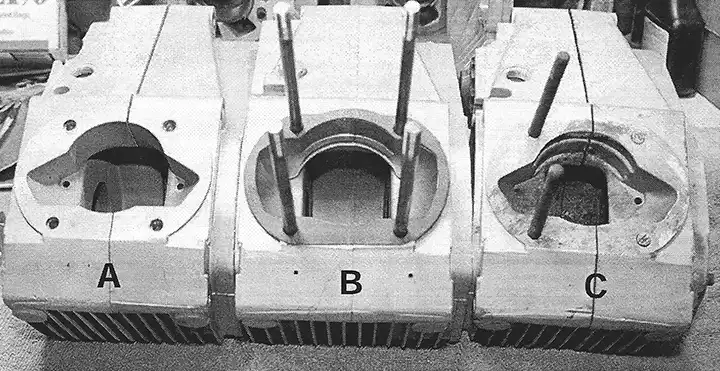

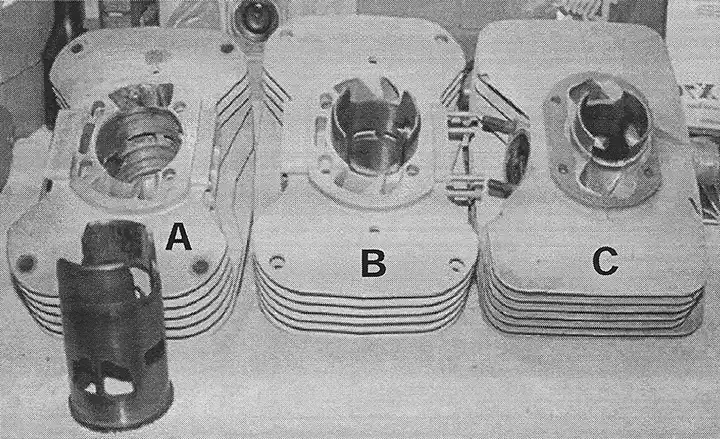

Knowing that in the past, Penton sold "152cc conversion kits", we set about looking for parts and replacement parts (that was more of a decisive factor) to make an alloy barrel 152cc. Calls to our Penton parts vendors revealed that a stock of Wiseco pistons was available, but no replacement ring sets were available. Without a supplier for replacement rings, we started thinking bigger. We had a piston for the short cylinder (1977 and up) 175 to compare with a 125 piston. The height from the wrist pin to the top outer edge of the piston was the same. The Penton 175 used the same stroke as the Sachs 125. It looked like it would work, as long as we did not try to go larger than 1st over before replacing the custom liner that we would have to make. Machining out the stock Sachs "B" aluminum cylinder as wide as it could be bored and have a liner machined to fit would leave us with a very thin liner.

We ordered a standard and 1st over piston. While we were waiting on their arrival we received an e-mail from an internet friend in Holland. He told us that their team used Monarchs with 175 KTM top ends in the 70's to win gold in the SixDays. It took me only ten minutes on the phone to locate a cylinder head and pipe for the 77 top end ( chuckle, chuckle).

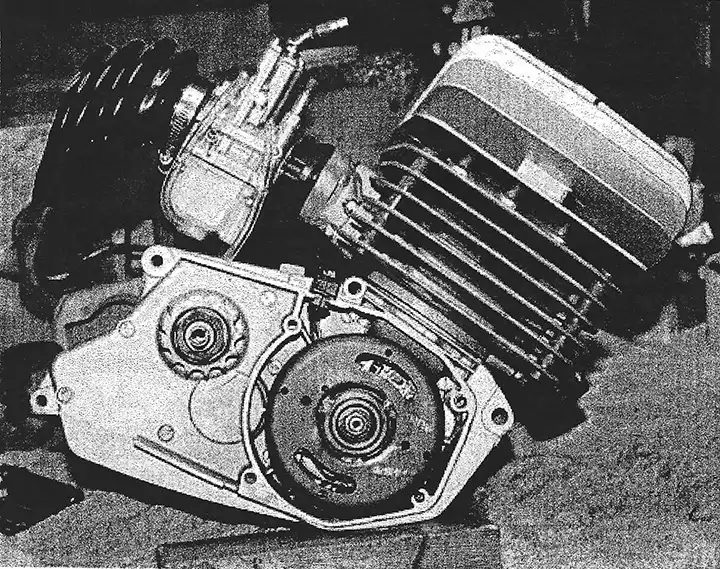

The cylinders have the same bolt pattern, so the 175 cylinder slid almost all the way down into the case opening. Normal "A" or "B" series Sachs cases will have to have the case opening machined out to fit the 175cc liner. The inlet to the transfer ports did not line up well. Due to a lack of gasket sealing area, we had to find a local welder who could weld the rear cylinder to fill in the crankcase/ gasket sealing surface on the back edge of the cylinder transfer ports. To get the cylinder all the way into the cases, the liner had to be removed and shortened at the bottom edge with a lathe. After the transfer ports were welded up, they had to be machined flush and the bottom of the cylinder lapped to provide a level sealing surface.

The crank was balanced by Falicon. The 175cc short piston was 1-1/2 ounces heavier than a 125 piston. So some attention had to be paid to the crank balance. Based on the amount of metal actually removed, re-balancing the crank we had was not necessary. The crank was mounted with a new A-rod kit from Euro-Rods and a NOS KTM 175 63.5mm short piston.

The head we ended up using was from a 1972 to 75 175 motor. Due to differences in combustion chamber shape, we ended up with lower compression than what was standard on a 1977 and up 175.

A 73-74 Jackpiner exhaust was massaged ever so slightly to fit in the 125 frame. A clamp-on SuperTrapp was welded to a stub replacing the stock stinger, silencer combo. A 2 inch stub of 3/4 EMT was used and a shroud fabricated out of muffler tubing from the local auto parts store. Then came the fun part, building a flange type intake manifold from an Amal intake and some sheets of aluminum plate. A few whacks with the hammer to the pipe, and the carburetor fit under the pipe and above the cases.

Unknowingly, the five speed gearbox we chose provided some additional benefits with it's wider gears. We do not currently know how much stronger the five speed box is, but it was considered necessary for the 182cc version Monarchs used to run the 250 class in the ISDT.

Lots of like new and new old stock parts went into the bike to make it a fairly complete historical representation of a vintage enduro motorcycle. The blue fuel tank will be graced with a set of custom vinyl sticker that say "Six-days l75cc".

The next several weeks saw extensive testing. with different Lectron needle and power jet configurations. The Lectron carb had a few eccentricities in store as we learned what we know about tuning it. The SuperTrapp, Lectron carburetor and lowered compression came together to form a power characteristic that is smooth and spread evenly throughout the power band. The engine leaves the impression of having two power bands. The first is likened to a mild trail bike. The second is like a hot 125 "B" motor with a lot more torque.

We used a Bosch Magneto (points type) from a military 125 engine. We like it better than the Motoplat. Timing is set at 3mm BTDC.

At this point in time, we have about 100 miles on the engine. It has worked out so well, that we don't plan to change anything unless we find some weakness caused by the boost in torque. We built the bike as an every day trail machine. If it holds up as well as the 125's of old, one engine rebuild is good for at least 6,000 miles with just the replacement of one ring set.

The bike weighs about 200 lbs fueled, is not as fast as a 175 Piner by maybe 4 Hp, but is a dream to ride. Old, Fat, out of shape enduro riders can go faster on it than on a stock Piner (chuckle, chuckle).

We had the help of the Lord (we did a lot of praying at times (GRIN) and the folks on the four continents with this project. We could not have done it without the support and advice we received from the POG members, The Vinduro group, and the folks that are members of Hercules IG in Europe. Our many thanks to all of you.

NOTE: cylinder is the shorter (6 fin) style made by KTM.

NOTE: carb bowl on Lectron is newest style that is opaque colored (not clear) which is alcohol proof.

(B) Modified Sachs "B" motor case showing enlarged openings for transfer ports and bottom of larger cylinder sleeve. Longer cylinder studs have been installed

(C) Stock Sachs "B" motor case before modifications with two cylinder studs for 125 aluminum cylinder.

(B) Finished KTM 175 "short" cylinder with liner installed. NOTE: transfer ports on bottom of cylinder "A" were welded up to increase gasket area.

(C) Stock Sachs aluminum 125 cylinder.

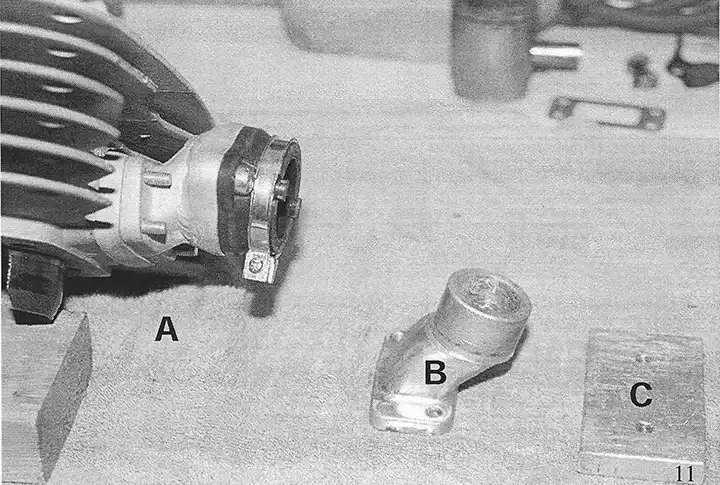

(B) Stock KTM aluminum intake manifold before modifications.

(C) Aluminum plate, drilled with 2 holes for rubber carb mount, before being welded and shaped.